|

Part 2

REMOTE

VOLTAGE-SENSING (for

the voltage regulator)

About the car

used for the “working model”

with

this REMOTE VOLTAGE-SENSING demonstration…

This

car was the best choice we had at our facility, when we

were shooting the photos.

It has an easy to access, stock, 12SI Delco

alternator, and genuine Delco voltage regulator in the

alternator.

The car also has five electric fans, lights, two

batteries, and other accessories to switch ON and use

power from the alternator.

(Which we needed, because significant voltage drop

would only occur with a large amount of current flow.)

We

used a SUN model VAT 40 (VAT for Volt, Amp, Tester), to

monitor system function and performance, and to measure

voltage drop in the long alternator output wire.

It was a handy arrangement that allowed for photos

of the VAT 40 meters, shot through the passenger side

window, while operating the car.

The

batteries and electrical control center in the car is

beneath the cargo bed, which is just behind the cab in the

custom Ranchero.

With removal of four screws, we lifted off the

cargo bed floor for access to show you this test.

For

the test demonstration, we prepared a 12 ft. length of

10gauge wire, which would connect between the alternator

output terminal and the

“main-power-distribution-junction.”

Chevy with V-8 engine in ’69,’70, and ’71

will have a 10gauge wire approximately this long, between

the alternator and the “main junction.”

Our test wire would give us a good representation

of what to expect with a typical factory built Chevy

system.

And

we also prepared a 12ft. long voltage-sensing wire, which

would connect from the voltage regulator in the alternator

to the “main power distribution junction.”

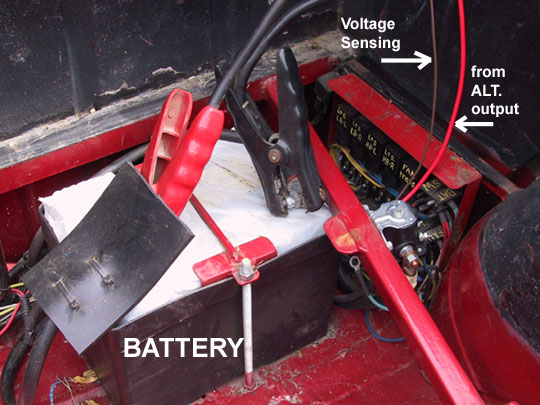

The

main “junction” at the Ranchero system, is the battery

POSITIVE cable stud, at the remote starter solenoid, which

is in the battery compartment.

We disconnected and set aside the existing 8 gauge

Tuff-Wire alternator wire at the junction. And we connected the prepared 12 feet long 10 gauge

alternator output wire and the voltage-sensing wire to the

battery POSITIVE stud at the remote solenoid.

The

battery positive stud at the solenoid connects to the

battery by 1/0 gauge, fine strand copper conductor cable,

and so during our tests, voltage measured at the battery

will be the same as voltage at this stud, which serves as

the main “junction” in this electrical system.

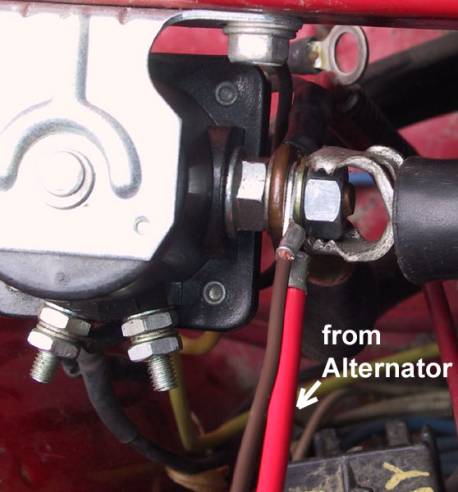

Moving

to the alternator area, under the hood, we connected the

12 feet long 10 gauge red wire to the output stud terminal

at the back of the 12SI alternator.

And we connected the voltage-sensing wire to the

regulator terminal at the two-wire plug-in connector.

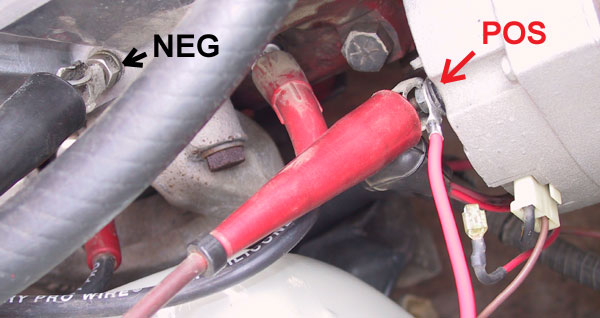

We

also connected the EXTERNAL VOLT METER leads of the Sun

Vat 40. The

NEG voltmeter lead is connected to a clean, valve cover

stud at the engine. And

the POSITIVE VOLT METER lead is connected directly to the

alternator output stud.

This

would allow the SUN VAT 40 to read voltage at the

alternator, during testing.

For

many years, the VAT 40 was the most popular of equipment

in professional automotive shops concerned with testing

alternator systems, starters, batteries, and voltage drop

problems.

In

alternator test mode, the BLUE, 0-100 AMP scale at the

upper meter is the one we are reading.

And the GREEN 0-18volt scale will apply to testing,

except when actually measuring voltage drop across a

cable. For

voltage drop testing the 0-3volt scale is more sensitive

and accurate, this setting is available when the VOLT

SELECTOR is switched to “EXT. 3V.”

Notice

the “VOLT SELECTOR” switch, at the lower left corner

of the photo. A

close up of the switch is shown in a photo below.

We will explain the switch and call out the setting

of the switch throughout this photo series.

When

the VOLT SELECTOR switch is set to “INT. 18V.” the

voltmeter in the VAT 40 reads from the large clamps

connected directly to the battery.

(Shown in next photo)

Set to “EXT. 18V. the VOLTMETER on the SUN VAT 40

reads from the small volt meter leads, which were shown

connected to the alternator in a previous photo.

And when set to “EXT. 3V.” the VAT 40 reads

voltage from the external voltmeter leads and displays the

reading on the 0 to 3 VOLT (black scale) at the voltmeter.

This 3 volt scale is very useful when measuring

voltage drop through a cable or wire.

Simply connect a volt meter lead at each end of the

wire, power up the circuit, and the voltage drop in the

wire (or cable) will be displayed on the 3 volt scale to

the nearest tenth of a volt.

The

large cables of the VAT 40 (booster cable/jump start like

clamps) are connected directly to the battery terminals.

These cables will allow the VAT 40 to read voltage

at the battery, when the selector is switched to INT. 18V.

These large cables also power-up the inductive AMP

meter built into the VAT 40.

(And these large cables may also be used to “load

test” a battery, with the adjustable “carbon pile”

LOAD TESTER BUILT INTO THE vat 40.)

The

AMP gauge in the VAT 40 reads current flow through a wire

simply by clamping the green probe around the wire (or

cable). Here

we have placed the probe around the 12 feet long red 10

gauge wire, where the VAT 40 can read alternator output.

(A distant view of this AMP PROBE is visible in the

second photo at this web page, which is the photo showing

the overall set up for this test.

The green AMP probe is on the front fender, it’s

on the white sweatshirt.)

To

see photos of the VAT 40 meter displays during actual

testing,

|