|

Part 3, the

last section of the

REMOTE VOLTAGE-SENSING

TESTS

(actual test results in photos)

In

this first test, we have switched the VOLTMETER to INT.

18V., and we are reading voltage from the battery (and

main junction).

With the remote voltage-sensing wire connected, the

voltage regulator is adjusting voltage at the junction and

battery to exactly 14.2 volts.

We have switched on the lights, cooling fans, and

heater fan to use current from the main junction in this

electrical system (The junction is the positive stud on

the remote solenoid, next to the battery.

The

upper meter on the VAT 40 is indicating about a 60 amp

alternator output through the 12 feet of red 10 gauge

wire.

As the battery was nearly at a fully charged

condition, most of this alternator power output is being

used to support all the systems we have switched ON.

In

the photo above, we have switched the VOLT SELECTOR to

EXT. 18V., and now we are reading voltage at the back of

the alternator.

Voltage at the back of the alternator is almost

exactly 1 volt higher than it was at the battery in the

previous photo, as the remote voltage-sensing is

compensating for the voltage drop in the long alternator

output wire.

Alternator

output is slightly higher in this photo than the in the

previous, as we left the lights ON while taking a break to

answer a tech support phone call.

Now the alternator is supporting the cooling fans,

headlights, heater fan, and plus it is recharging the

battery!

In

the above photo, we have switched the VOLT SELECTOR to

EXT. 3V. and connected the external voltmeter lead wires

in parallel with the 12 feet long 10 gauge alternator

output wire. Reading

the 3 VOLT, black scale at the lower meter, we are

measuring almost exactly a 1 volt drop in the long

alternator output wire.

(The next photo will show the external volt meter

lead connected at the “junction,” which is the battery

POSITIVE stud on the solenoid.)

The 1 volt drop is exactly the voltage difference

between the two previous photos, which compared the 15.2

volts at the back of the alternator to the 14.2 volts at

the junction.

This

directly measured voltage-drop test serves as a very good

cross-reference check to verify accuracy of

the voltage difference between the two previous

photos. (All

laboratory tests should have a “control test” or at

least a “cross-reference test” to verify accuracy.)

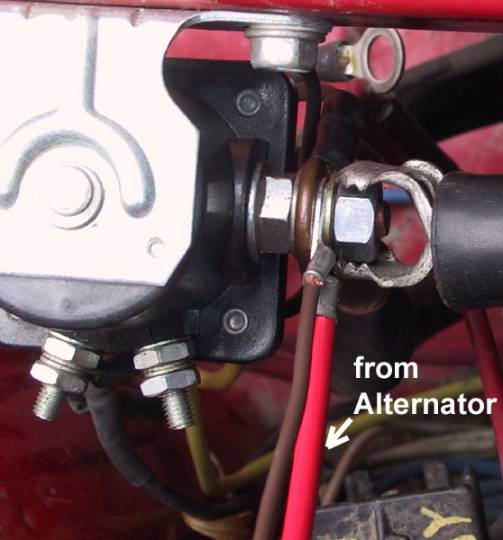

And

the above photo shows a close-up view of the external

voltmeter lead wire, connected to the junction/stud on the

solenoid.

(The alligator clip on the hex-nut at the stud is

the SUN model VAT 40 external voltmeter lead wire.)

This connection of the VAT 40 voltmeter was used

for the previous photo, where we measured a 1 volt drop on

the EXT. 3V. switch setting.

The remote voltage-sensing feature is

not available with “ONE-WIRE” alternators. With the ONE-WIRE alternator, the internal voltage regulator

can only adjust voltage at the alternator.

To show how the ONE-WIRE alternator would behave in

this test, we let our existing THREE-WIRE alternator take

voltage-sensing sample from the output stud at the back of

the alternator. Then

voltage-sensing with our existing THREE-WIRE alternator

would behave the same as with a ONE-WIRE alternator.

The remote voltage-sensing feature is

not available with “ONE-WIRE” alternators. With the ONE-WIRE alternator, the internal voltage regulator

can only adjust voltage at the alternator.

To show how the ONE-WIRE alternator would behave in

this test, we let our existing THREE-WIRE alternator take

voltage-sensing sample from the output stud at the back of

the alternator. Then

voltage-sensing with our existing THREE-WIRE alternator

would behave the same as with a ONE-WIRE alternator.

ONE-WIRE

alternator simulator test underway! ONE-WIRE

alternator simulator test underway!

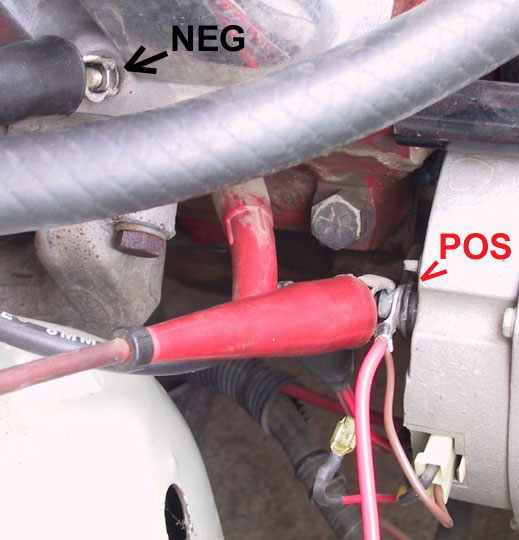

We

made a short length wire, which would connect the

voltage-sensing terminal at the two-wire connector to the

output stud at the back of the alternator.

And

at the alternator wiring we removed the long length of

remote voltage-sensing wire, and installed our new jumper

wire. The

voltage regulator will now read voltage at the alternator

and make adjustments to output as required to maintain

about 14.2 volts at the alternator.

(Same as with the ONE-WIRE system.)

Also

notice in the above photo that we have once again

connected the EXTERNAL VOLT lead wires to the alternator,

so we can compare voltage at the alternator to voltage at

the battery.

Notice

in the above photo we have switched the VOLTmeter to EXT.

18V., and we are now reading 14.2 volts at the alternator.

Also notice that the alternator is producing about

a 55AMP output, as once again we have switched ON the

cooling fans, lights, and heater fan, while running the

engine.

And

in the photo above, we have switched to INT. 18V., and now

we are reading voltage at the battery, which is next to

the main junction. The cooling fans, lights, and heater fan are all switched ON,

and we are still measuring about a 55AMP output from the

alternator.

But

now, voltage drop in the alternator output wire has

reduced voltage at the battery to the 13.2 volt level.

We

still have the same 1 volt drop in the 12 feet long, 10

gauge alternator output wire.

But with the voltage regulator making adjustments

at the alternator, we are left with low voltage at the

battery and main junction.

IN SUMARY

It

really pays to “charge ahead” with remote

voltage-sensing.

Our tests were representative of a factory wire

harness layout, with main-power distribution from a

junction in the wiring, and a long wire from the

alternator output to the junction.

NOTE

that the amount of resistance in a wire increases when the

wire is warm. (GM

engineering data shows about a 25% increase in resistance

when wire temperature is increased from 70 degrees to 160

degrees F.) Temperature

during this test was about 65 degrees F, which is cooler

than we would expect at the alternator output wire under

the hood of a Chevy. And this is especially important

considering that parts of the alternator output

wire and the battery charging wire are above the

radiator!) In

the case of wires being considerably warmer than with our

test, the amount of voltage drop would be greater with

increased resistance.

And then the REMOTE VOLTAGE-SENSING option becomes

even more important.

The

tests clearly show that REMOTE

VOLTAGE-SENSING is the key to good electrical system

performance when using this factory-type wiring layout.

See

more about remote voltage-sensing in our ONE-WIRE compared

to THREE-WIRE alternators page, in the ELECTRICAL TECH

section of this web site.

|