|

It all

STARTS with knowledge of how things work!

REMOTE

VOLTAGE-SENSING IS THE KEY TO GOOD ELECTRICAL SYSTEM

PERFORMANCE… It

lets the voltage regulator make adjustments where proper

voltage level will do the most good.

Remote

Voltage Sensing

is not a new idea;

in

fact many factory original systems have been using it

for years (even with external voltage regulators back in

the 1960’s).

All

voltage regulators take an electrical system reading,

and constantly monitor the voltage level of the system.

For most temperatures and conditions, the

textbook battery voltage level when topping off a fully

charged battery is about 14.2volts (with a 12 volt

system).

The voltage regulator will adjust alternator

output in effort to maintain that 14.2 volt level, under

normal operating conditions.

Therefore, most electrical system parts (lights,

ignition, and accessories) are designed for best

performance when operating at about 14volts.

Electrical system

performance drops off abruptly when voltage delivery to

the parts is only slightly low—and so we really like

to see those parts operating at 14volts!

With

involved wire harness construction used to deliver power

to various parts of the electrical system, some of the

wires will be long in length.

Most often, the dash area with switches and fuse

box is far from the alternator.

And under the hood, the battery may be at the

opposite side from alternator mounting, which will also

require a long wire. The

long length of wires will result with “voltage

drop.”

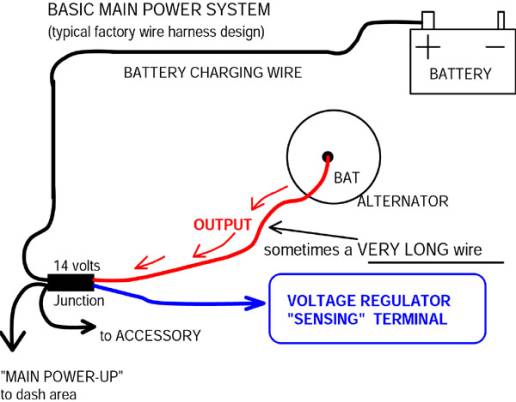

Considering

the spread-out location of electrical system parts on the

car, often the most efficient and practical layout is to

route alternator power output to a centrally located

“junction.” And

then from the junction, power will be distributed to

various parts of the electrical system.

Also the electrical current used to charge the

battery will be routed from the central main junction to

the battery. The

diagram above shows such a system; and it is a system that

was successfully used with many factory-built wire harness

layouts.

The

key to good performance

with

the layout described above is to let the voltage regulator

make adjustments to voltage level at the junction.

(And then the voltage at the battery and other

parts of the system will follow the voltage level

maintained at the junction.)

The voltage regulator can maintain 14.2 volts

at the junction, even though the junction may be many feet

of wire from the alternator.

But REMOTE VOLTAGE-SENSING must be

enabled to make it all happen.

The diagram above shows this basic layout; and it

was successfully used with many cars during the Muscle Car

period.

Certainly the Chevy design layout was this type

during the Muscle Car period.

(Although the particulars and location of

components did get moved around during that period of

years.)

When using this factory wire harness layout,

and up-grading to modern and more powerful alternators; it

is of critical importance to let the voltage regulator

read and adjust voltage at the junction.

And we call this function “REMOTE

VOLTAGE-SENSING.”

(“REMOTE” because the voltage regulator

takes care of voltage level at a place away from the

voltage regulator, alternator, and battery.)

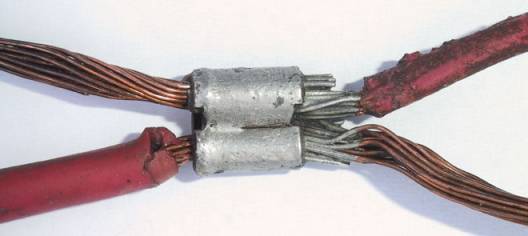

The

photo above shows an actual “main junction,” which we

removed from a Chevy factory original wire harness.

Note that the splice used for the factory

“junction” was crimped and soldered; these

factory splices are very reliable!

In our BASIC MAIN POWER diagram, we simply labeled

this part “junction.” When working with an original harness, which is in good

condition, capacity of the wiring and this junction is

adequate for alternators of moderate output.

(Output as much as the Delco 12SI 78amp unit works

fine, but REMOTE VOLTAGE SENSING must be properly wired.)

However,

as anyone can see, the junction is not friendly for

addition of accessories–The factory never intended to

add main power-up wires for electric radiator fans or

other high current draw accessories to this junction.

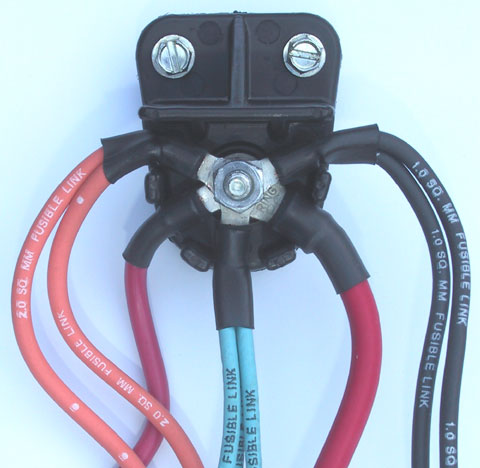

The

“junction” shown in the above photo is M.A.D.’s part

#CN-1.

This is the most sensible, compact, friendly to

work with junction in the industry.

When up-grading to high powered alternators, a new

heavy gauge cable can be routed from the alternator

directly to the this junction.

The factory dash area main power-up wire can be

transferred to this junction.

Many accessories can be added to the junction.

The battery charging wire of optional gauge size

can be routed from this junction to the battery.

And fusible link wire short circuit protection can

be installed at all outgoing circuits from the junction.

When customizing the “BASIC MAIN POWER SYSTEM”

shown in our diagram, this part#CN-1 is well suited for

the job!

The

OLD and the NEW,

both with REMOTE VOLTAGE-SENSING FEATURE

Back

in the old days,

when

our Chevy Muscle Cars were new, technology was more

primitive than today.

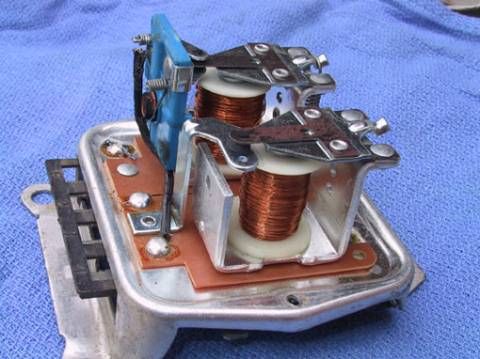

The above photo shows a typical external voltage

regulator used with most GM car alternator systems from

1963 thru 1972 models.

Of the four terminals at the voltage regulator, one

of the terminals served as the “voltage-sensing”

terminal, and it was wired to the “main junction.”

The

photo above shows construction inside of the old external

voltage regulator.

The original parts were mechanical, with two major

functions built in.

(1)

The “vibrating point type” voltage regulator is

at the foreground in the photo.

It’s a magnetic winding and moveable arm with

contact points assembly, and it was used to control

current to the alternator field winding.

(The points opened and closed many times per

second, thus it was often called the vibrating point type

regulator.)

Full current flowed to the alternator field when

the points were closed, making a strong magnetic field at

the alternator, which increases output.

It is interesting to note that when the points were

open in this system, current to the alternator field was

never entirely disconnected.

When the contact points were open, a small amount

of current still flowed to the alternator field through

resistors mounted at the underneath side of the regulator

assembly.

No doubt this action with the resistors smoothed

out the operation and reduced erosion of the voltage

limiter contact points.

And the system also needed to maintain at least a

small amount of alternator output to keep the “field

relay” turned ON.

(2)

The second magnetic winding with movable arm and

contact points was a “double throw” relay.

There are stationary contact points above and below

the contact at the movable arm.

Spring pull moved the arm to close one set of points,

which directed a small amount of current to the alternator

field, resulting with a small amount of alternator output.

When the alternator begins to make this small

amount of output, current from the alternator stator

powered up the magnetic winding, which pulled the movable

arm to close the other set of contact points.

As this other set of contacts closed, the regulator

was connected to main battery power source at the

“junction” in the wire harness.

When the system was first activated, a small amount of

current flowed from the ignition switch to the voltage

regulator through a 10 to 15 ohm resistance wire built

into the dash harness.

(And if the car had a warning light at the dash,

the warning light was wired in parallel with the

resistance wire.)

This was our ignition switched ON/OFF and warning

light circuit with the old externally regulated alternator

system.

And

through the “field relay” in the old external voltage

regulator, we had REMOTE VOLTAGE-SENSING from the main

“junction” in the wire harness.

Not all systems had

Not all systems had

the

REMOTE VOLTAGE-SENSING option.

Some

of us in workshops years ago, used to install this

“field relay” function, using an ordinary relay, to

create our own version of the REMOTE VOLTAGE-SENSING

function.

The MOPAR, two-wire voltage regulator system, both

the early mechanical and later electronic, did not have

the remote voltage-sensing feature.

And especially with powerful alternators and

involved wiring, as with Dodge motor home chassis, the

remote voltage-sensing feature is the best way to make a

system behave properly.

We

also had to install our own main power distribution

system, as the factory system with AMP gauge at the dash

was too lightly built for an electrical system so powerful

as a motor home needed.

(Readers with more interest in the MOPAR system

should read our “BY-PASSING OLD AMP GAUGE” pages, at

this tech section.)

|

Go

for the best!

|

Thankfully

nowadays, the voltage regulator will typically be a small,

electronic unit, inside of the alternator.

The function is more reliable, more accurate, and

more consistent than the old mechanical units.

The

voltage regulator in the photo above is used with the

Delco 10SI and 12SI alternators.

Notice that the voltage regulator above has two

flat blade male terminals (see arrows).

There is actually a third terminal of this voltage

regulator, which is the ground at one of the three

mounting screws. One

of the two flat blade terminals is wired to an ignition

switched ON/OFF source, and this circuit can also be used

to operate a dash mounted warning light (The warning light

is an option, not a requirement).

The

other of the two voltage regulator terminals is the

voltage-sensing terminal, and through this terminal the

voltage regulator will monitor electrical system voltage

and make adjustments to the alternator output in effort to

keep system voltage at about 14.2 volts.

When

using the “main junction” power distribution wiring

system, it is very important that the voltage-sensing

terminal of the regulator is wired to the junction.

And when installing the SI series alternators as a

retro-fit up-grade, with a factory type harness using a

main “junction” for power distribution, it is of

great importance to make use of this REMOTE

VOLTAGE-SENSING feature built into the regulator.

In

the next web pages we have photographed a demonstration of

the remote voltage system function and performance.

A lot of photos are used in the next part—and not

much reading. It’s

really quite interesting to see this system work.

To

see the REMOTE VOLTAGE-SENSING feature in action, click

here to continue

|