|

Cooling system work should

include testing the

Water

Temp gauge accuracy.

The real story begins here!

The real story begins here!

by

Mark Hamilton

Is it HOT,

or NOT?

Maybe the new Water Temp gauge just simply is not accurate!

When

first firing up a newly constructed Hot Rod, it’s especially important to know

if a Water Temp gauge is dead-on accurate or “far off the mark”.

First

on the agenda with a newly constructed Hot Rod will be to run the engine at a

moderately fast RPM to break in the camshaft and valve lifters. Typically we do this engine “break-in

period” while the car is sitting in place, but with the engine running at

highway cruise RPM. The friction of the

lifters rubbing on the cam lobes will actually burnish the surfaces to a finish

that must last for the life of the cam and lifters. (“Roller Cams” are an exception.)

The

significance of noting that the car will be sitting in place, rather than

rolling at about 60mph, is that we will not have the airflow to assist in

cooling. Also, the fresh engine will

produce more heat than it will after break-in.

After the break-in period we may tune the engine, which can further

reduce the coolant “normal” operating temperature.

The

break-in period is a critical time with the new engine, and sometimes it’s

difficult to keep the engine cool while running in place at high RPM during the

break-in period. It pays to check

the Water Temperature gauge before starting the engine for

break-in. By checking the gauge ahead

of time, we will know where we actually stand with the water temperature.

We should also consider that a “restofication”

project might include many changes that can affect operating temperature of the

engine coolant. (Some of us use the

term “restofication” to describe a restoration with modifications and

up-grades.)

With a new engine, we may have a higher compression

ratio, a new distributor may have a different advance curve, a new carburetor

may have changed the air/fuel ratio, and we may have also changed rear-end,

transmission, and tire diameter, resulting with a different MPH to RPM ratio.

All of the previously mentioned topics can affect

the operating temperature of the engine coolant. If we add to the car’s makeover a new radiator of different

design, a different cooling fan, and a new Water Temp gauge—then

it will be a very good idea to verify accuracy of the new water temp gauge.

The same is true when buying a complete, running

and driving car. It takes some driving

time to learn what “normal” temperature is for a particular car. Actually for any car, it’s important to know

where we really stand with coolant temperature.

THE TEST

Most of us already know that water boils at 212 degrees F, at

sea level, in an open container. But

when performing this test please be aware that water in an open container boils

at a lower temperature at higher altitudes. The table below provides figures for doing

this test at altitudes higher than sea level.

|

Elevation (in feet)

|

Boiling point of water

(in an OPEN CONTAINER)

|

|

0 ft. (sea level)

|

212.0 degrees F

|

|

1,000 ft. (above sea

level)

|

210.1 degrees F

|

|

2,000 ft.

|

208.1 degrees F

|

|

3,000 ft.

|

206.2 degrees F

|

|

4,000 ft.

|

204.3 degrees F

|

|

5,000 ft.

|

202.4 degrees F

|

|

6,000 ft.

|

200.6 degrees F

|

|

7,000 ft.

|

198.7 degrees F

|

As seen in the table above, the boiling point of water in an

open container is reduced about two degrees F for every 1,000 feet we go up in

altitude. With a comparison between sea

level altitude and a location at 6,000 feet altitude, the difference when doing

this test at the different altitudes would result with a nearly twelve degrees

change in the gauge reading. Twelve

degrees of change would be noticeable on a good Water Temp gauge.

With mechanical gauges, the test may be slightly easier to

perform before installing a new Water Temp gauge, but the test can also be done

if the gauge is already in the car.

We did this test at our M.A.D. Enterprises workshop, which is

at about 1,000 feet elevation, near Springville, California. And as the photo shows, this gauge is

accurate!

This

gauge is an imported, low-budget model, by Auto Meter. It is the mechanical model, which the author

has found to be typically more accurate and more responsive than the electrical

gauge models.

It’s good to choose a gauge with a 270degree needle sweep rotation, as shown in

the photo above. Accuracy is typically

better and small temperature changes are easily recognized with the greater

sweep of the needle.

(Ditto

for oil pressure gauges! The author

also prefers mechanical oil pressure gauges with a 270degree needle sweep,

compared to the electric models and gauges with less needle sweep. The quick response of the mechanical gauge

can be helpful with spotting early warnings of an engine problem!)

It’s

typical that any gauge from Auto Meter would be accurate, as Auto Meter is

famous for bringing good equipment to us Hot Rodders.

But

the author can no longer say the same good things about all models of Stewart

Warner gauges.

Several

years ago… A “budget model” three-gauge

set of Stewart Warner gauges was installed in a customer’s car. The budget model Water Temp gauge was the

model shown above. Shortly after

installing the gauges, the customer complained that his car always seems to run

hotter than he would like to see. After

considerable money spent in attempt to see the engine run cooler, the gauge

still showed that the car was running too warm, in fact borderline over-heating

on hot days. (A costly new radiator,

and also a new thermostat and high performance water pump made no improvement

in the Water Temp gauge readings.)

We

used the boiling water test to check the Stewart Warner gauge in question, and

with the probe in boiling water the gauge displayed approximately 235 degrees

F! During a phone call to Stewart

Warner in hopes of getting a replacement gauge, the author was told “Not to worry;

that model of gauge is only accurate to plus-or-minus 14%.” Well that’s a handy explanation, since at

actual 200degrees coolant temperature a 14% error would cause the reading to be

28degrees in error! We might as well

not even have a coolant temperature gauge if it cannot be more accurate than

those measurements. But not to

worry, we tossed it in the trash dumpster where it belongs, and bought

a better water temp gauge. Happily the

new gauge checked out fine and it pleased the car owner to finally see his car

running at “normal” water temperature.

And

the reason for the above discussion is not an intended bashing of all Stewart

Warner gauges, but only to point out the importance of testing the Water Temp

gauge for accuracy. We use the Water

Temp gauge to monitor cooling system performance, and we should know that the

gauge is giving us correct information.

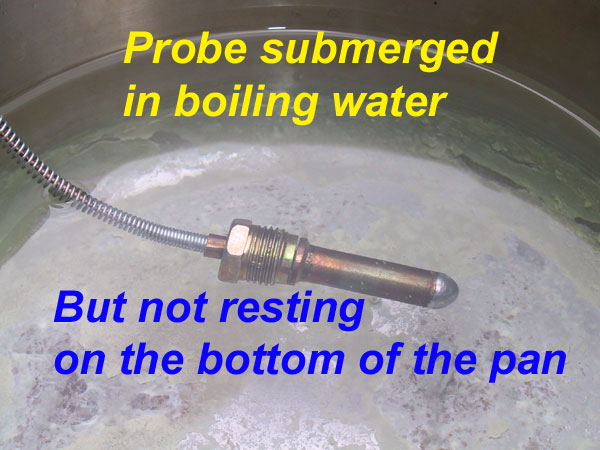

When performing the test be aware that the probe should be

submerged in the boiling water, but not laying at the bottom of the container. The electric hot plate beneath the cooking

pan, or a burner flame beneath the pan, will likely make the metal at the

bottom of the cooking pan hotter than the boiling point of water. If the probe was resting on the bottom of

the pan it may sense the hotter temperature of the metal pan, and then the test

would not be accurate.

This boiling water accuracy test for the water temp gauge can

be used with equal accuracy for mechanical and electric gauges. With electric Water Temp gauges, the test

should be done after the gauge and wiring has been installed in the car. (Because a wiring problem could affect the

gauge performance.) When testing

electric gauges that are already installed and wired, we can bring the electric

hot plate and cooking pan to the car.

Either we can put an insulated cover on the air cleaner to support the

hot plate, or put the hot plate on a stand next to the car.

GROUND THE “SENDING UNIT” WHEN TESTING ELECTRIC GAUGES

A

very important part of the test procedure for electric gauges is connection of

a ground wire to the threads of the water temp switch for the gauge. For this ground wire, the author uses a test

lead with a cable clamp that was originally intended for use with small battery

chargers. (Because it fits over the large

diameter threads of the temperature switch, but a small alligator clip will not

fit.) Connect the other end of the test

lead to a good ground, in example a carburetor mounting stud typically works

well.

Then,

make an extension wire from the existing original wire that will allow the

sending unit to reach the hot plate area.

18gauge, 16gauge, or 14gauge wire is fine for the job, and the

calibration reading at the gauge will not be affected with the wire at extended

length.

The

test is very useful with factory gauges too, and especially practical when a

factory gauge does not have degrees of temperature marks. The factory gauge shown in the above photo

is marked only at “COLD” and at “HOT.”

But with the boiling water test, at least we will know where the gauge

will read with the coolant temperature at about 210 or 212degrees F. (That is 210F or 212F with the testing

performed at about sea-level altitude.)

One

lap to go! One

lap to go!

Please

click here for Part 2;

There’s some good photos and reading on placement of the probe for the Water

Temp gauge.

|