|

|

The

Trend Setter

|

Part

2

ONE-WIRE

compared to

THREE-WIRE

ALTERNATORS

In

recent years

it seems that the term ONE-WIRE has become a much-used

buzzword, and ONE-WIRE is often used by people who do not

understand it. Among

the GM SI series alternators, there is both the ONE-WIRE

type and the THREE-WIRE type. Many people who have called did not know that not

all alternators with a built-in voltage regulator are

“ONE-WIRE” types.

Many people simply refer to all alternators

with built-in voltage as ONE-WIRE.

(Lumping the THREE-WIRE and the ONE-WIRE, both with

built-in voltage regulator, into the same classification;

is incorrect and results from lack of being informed.)

With

this technical feature we will attempt to discuss,

compare, and provide the information needed to decide

which system is the best for particular applications. (ONE-WIRE, or THREE-WIRE, both with a built-in voltage

regulator.) And

we will discuss the advantages and disadvantages of each

type when used in different applications.

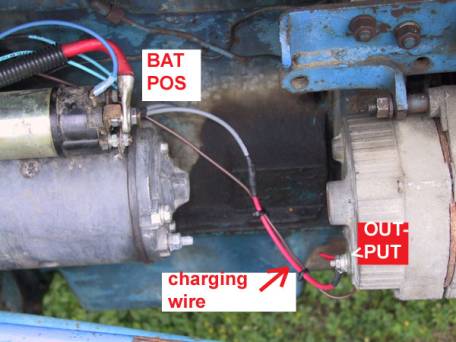

Shown

above is the first-generation GM Delco-Remy alternator

with built-in voltage regulator.

The “ONE-WIRE” alternator shown above only has

a heavy gauge wire connected from the output terminal to

the battery. The obvious advantage is that not much knowledge is needed to

wire it! (The

ONE-WIRE alternator shown above is the 10SI model.)

It’s

logical that Delco-Remy Division of GM would have

originally designed the “ONE-WIRE” version of their

10SI alternator. These

alternators have been widely used on agricultural and

industrial machinery.

Considering the number of companies building

tractors, forklifts, engines for irrigation pumps, air

compressors, and the many other examples of machinery

requiring an alternator, it would have been simple to

furnish the ONE-WIRE.

There’s not much to teach about wiring the

“ONE-WIRE.” And

so the “ONE-WIRE” alternator would have avoided a lot

of “how-to-wire-it” teaching sessions, which can occur

when supplying the THREE-WIRE system.

(Trust us, the tech calls can drive a person MAD!

And the need for knowledge of proper wiring is why

we made the part#ALT-1 kit, which comes with good

instructions and all the proper wiring parts.)

If

the “ONE-WIRE” would have worked well with the

complicated wiring involved for support of all the many

accessories on cars, then over the years GM could have

saved a fortune in wiring.

But GM did not compromise electrical system

performance in this area.

They did spend more money for engineering and

wiring to install the THREE-WIRE alternators, which will

deliver best performance. And as we shall see, there really is value to the little

extra work required to install the THREE-WIRE system.

The

“ONE-WIRE” alternator is best suited for

applications that need the alternator only for a battery

charger. Okay,

so it’s a little radical to use an old farm tractor as a

model in a site for High Performance cars. Ha!

But the tractor example makes a strong point about

the ONE-WIRE alternator system.

This

tractor is an application that only needs the alternator

for battery charging purpose.

This simple tractor has no lights, no

electrical accessories, and not even an ignition system

(The engine is a diesel model.)

And the

wire harness on tractors and most other

machinery is short in length, with fairly

heavy gauge size wire.

The ONE-WIRE alternator could satisfy the battery

charging needs on this simple old tractor.

It’s

important to notice the short-in-length charging wire on

the tractor. Significant

voltage drop will not occur with the battery charging wire

only a few inches in length.

And there are no accessories to hook-up downstream

from the alternator. The “remote voltage sensing”

option available with the THREE-WIRE is not needed with

this tractor application.

However…

Even the most simple of applications, like the

old tractor, can use the THREE-WIRE type alternator with

built-in voltage regulator (the two wire plug-in

plus the “charging wire).

Although it must be properly wired, the THREE-WIRE

type does work equally well for the tractor application.

The added benefit of wiring the tractor for the

THREE-WIRE alternator is that replacements will be less

expensive and more easily found.

(Since the “THREE-WIRE” type was used on many

years of all GM cars and trucks, it can be found at about

any place where auto parts are sold, and usually for far

less money than the special “ONE-WIRE” type.)

And a Warning Light on the dash in addition to a

gauge will be an option when the THREE-WIRE is installed.

TIPS

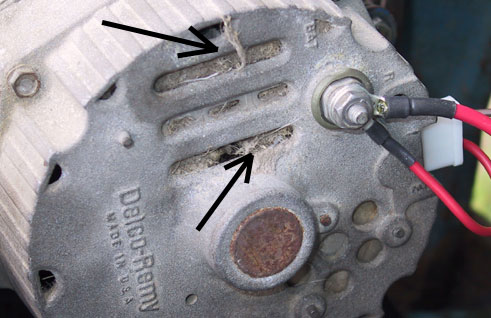

Notice the debris at the air-intake for cooling,

which probably resulted from operating in a dusty, dirty

environment. (see arrows) This needs attention, as

alternators require adequate cooling. What we should see through those air-intake openings is the

rectifier heat sink with aluminum cooling fins. Sometimes plugged air-intake is also a problem when

fiberglass hood insulators deteriorate on cars and trucks. That debris will have to be cleaned out of there.

The cooling fan at the front of these alternators

is an exhaust fan, and it pulls air in through the back of

the alternator where the rectifier heat sink is mounted. (That’s why the debris is stuck in the back-of the

alternator.)

Cooling

is very important to an alternator.

Machinery built by man is never 100% efficient.

But energy is never lost or destroyed (only

converted). Briefly

speaking, if an alternator design was only 50% efficient,

and 4 horsepower was required to operate the alternator;

then we would get 2 horsepower worth of electrical energy

from the alternator and 2 horsepower worth of heat energy

from the alternator.

And of course, as with engines, increasing the

output potential will increase the heat output. (Heat is

the by-product of efficiency loss.)

When

alternator output rating is increased, the cooling

capacity of the alternator should also be increased.

Beware of budget 100 amp alternators built

upon the 63 AMP rated, 10SI model case design, and

with only original design rectifiers and fans. The output potential is nearly doubled, and the cooling

capacity is reduced since the case will be filled with

more windings. And

be thankful for good companies like POWERMASTER, who

improve the cooling capacity when they increase output

potential. (POWERMASTER

also gives us the options of both “THREE-WIRE” and

“ONE-WIRE” alternators.)

The

difference between the ONE-WIRE and THREE-WIRE alternator

is the voltage regulator.

The Delco part # D680 voltage regulator shown above

is used in both the 10SI and 12SI THREE-WIRE models.

The same model of alternator can be assembled with

different types of voltage regulators (for ONE-WIRE or for

the THREE-WIRE system).

We do have options, and the choice is ours to make.

The

voltage regulator for the “ONE-WIRE” alternator is

often referred to as “SELF-EXCITING.”

The “self-exciting” terminology probably comes

from the old generator days, when testing the generator

output required “exciting” the field winding (which

involved powering-up the field winding so that it would

make a maximum strength “magnetic field”).

And the “self” part of the term comes from the

voltage regulator turn ON function without the assistance

of a dedicated wire circuit.

How the ONE-WIRE

Voltage Regulator Works

The

iron core material next to the field winding in the

alternator will retain some magnetism after once being

magnetized with field winding power-up (during assembly).

After the engine has been started, and the

alternator is spinning, the existing weak magnetic field

from the iron core material will cause the alternator to

produce a small amount of current. This small amount of current is used to turn the voltage

regulator electronics ON (rather than wiring a special

wiring circuit to turn the voltage regulator ON).

And of course the faster we spin the alternator,

the greater the potential for output.

That is why sometimes we have to rev the engine

once to kick in the “ONE-WIRE” alternator.

(We have to spin the field in the alternator fast

enough to make sufficient current to turn ON the

“self-exciting” voltage regulator.)

How the THREE-WIRE

Voltage Regulator Works

(the

Turn ON & Warning Light circuit)

With

the “THREE-WIRE” alternator model built for cars and

trucks, one of the voltage regulator terminals is wired to

an ignition switched OFF/ON source.

And the OFF/ON circuit may also be used to operate

a warning light at the dash.

(The THREE-WIRE type can be wired with or without a

warning light at the dash.

The warning light is an option–not a

requirement.)

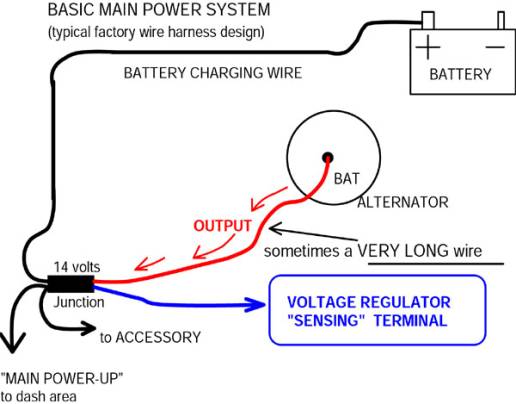

REMOTE

VOLTAGE SENSING, a THREE-WIRE advantage

The other of the two

plug-in wires at the SI series alternator is the

“voltage-sensing” terminal for the voltage regulator.

Through the sensing-wire, the voltage regulator

monitors electrical system voltage and makes adjustments

to alternator output.

The regulator will adjust alternator output as

needed to maintain the place where the sensing-wire is

routed (at about 14.2 volts).

And the sensing-wire can be routed to a place

remote from the alternator (downstream).

This “remote

voltage-sensing” feature is often a big advantage when

running with a factory type wire harness from the Muscle

car period (60’s and early 70’s period cars and

trucks). Then

the alternator output will be adjusted according to what

goes on far downstream from the alternator–at the main

power distribution junction, which operates the whole car

plus charges the battery!

click

here to continue

to

the last part of this ONE-WIRE compared to THREE-WIRE

feature

|