|

Part

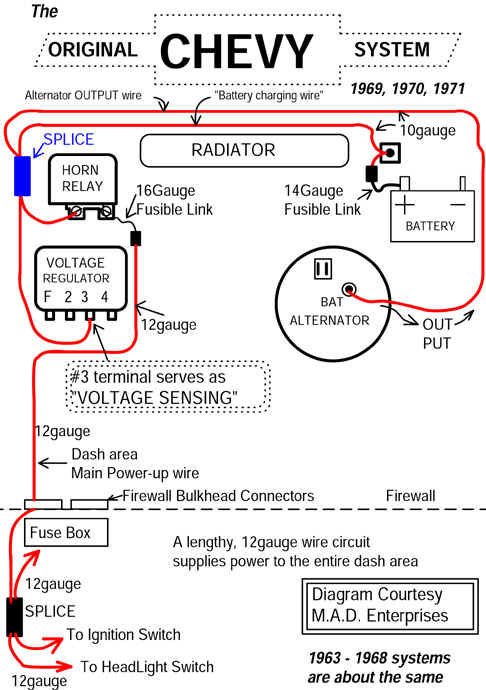

2, THE CHEVY MAIN POWER DISTRIBUTION SYSTEM

WIRING METHODS FOR

UPGRADING THE SYSTEM

The

best choice of layouts will depend upon the amount of

high-powered electrical accessories that will be added,

the condition of existing wiring, and if the battery will

be relocated to the rear or stay up front.

Three wiring methods are offered, and a diagram is

provided for the third method.

The third method provides the most significant

performance improvements, and that applies to simple cars

with 63amp alternators, or involved custom cars with

140amp alternators.

The first and

second wiring methods described below will still use the

Horn Relay buss bar for main power distribution.

And if accessories will be added (Radiator fans, or

other), main power wires to the new accessories should be

connected to the Horn Relay.

(1)

Simple method with battery up front:

We can up-grade to a “factory

style” alternator with built-in voltage regulator.

(A THREE-WIRE alternator is required, the

“ONE-WIRE will not work.)

The alternator with built-in regulator must be

wired to keep voltage-sensing at the splice.

This method lets the voltage regulator read and

adjust voltage at the splice and Horn relay area.

The system will be self-compensating for voltage

drop between the alternator and the point of main power

distribution. The alternator up-grade with this method

will behave the same as with the original factory

installed system with an external voltage regulator.

(The

more modern alternator with built-in voltage regulator has

much better output at low RPM and idle speed, better

reliability, and reduces clutter.)

This

method works well when up-grading the alternator, but

limiting the gross out-put rating to a modest level.

If the original alternator output wire is in good

condition, it can be left in place with this conversion

method. It’s

great with a “stock” electrical system and a 63-amp

alternator (“stock” model 10SI).

This

method can easily be accomplished with a minimum of work

and expense. The M.A.D. Part #Alt-1 wiring kit is all that

will be needed to install this wiring layout.

CONNECT

NEW ACCESSORIES AT THE HORN RELAY BUSS-BAR

Since

this layout operates like the original system, it’s very

important to note that any new accessories should get

power from the Horn Relay.

Proper voltage will be maintained at the Horn

Relay, but connecting accessories downstream from the Horn

Relay would result with lower voltage elsewhere.

In example, do not simply connect a fuel pump power

wire to ignition switched ON/OFF source at the fuse box or

dash wiring. Main

power to relays such as for fuel pump or for headlights

should connect at the Horn Relay, when using this original

CHEVY system.

If

the wiring is in good condition, and the battery will

remain up front, this method is fine for many

applications.

(2)

Alternate method, also with battery up front:

We can install a significantly

larger gauge size wire from the alternator to the Horn

Relay buss-bar, which can deliver more power from the

alternator to the Horn Relay buss-bar. (Although wiring

the regulator for “remote voltage-sensing” will still

be a good idea.)

New

8gauge Tuff-Wire is supplied with M.A.D.’s alternator

wiring kits, and the new wire will strengthen the system.

When installing the “stock,” 94amp model 12SI

alternator and powerful electric radiator fans, plus maybe

a new electronic ignition system, and a few other items, and

battery remaining up front, this is a simple and effective

up-grade. The

new 8gauge wire is also a very good idea when the

condition of the original alternator output wire is

unknown or has obviously been patched-up.

Like

the system above, the Horn Relay buss-bar is where we

should connect main power to headlight relays, fan relays

or other accessories.

The factory style “THREE-WIRE” alternator is

still preferred; it will still support a warning light at

the dash, it can perform remote voltage-sensing, and

better availability of replacements will be an advantage.

This

second method is good when installing a 78amp or 94amp,

model 12SI, DELCO alternator, and with limited accessories

connected at the Horn Relay.

(M.A.D.’s Part # ALT-1 alternator wiring kit will

provide proper wiring and instructions.

The 8gauge Tuff-Wire supplied in the kit will

handle alternator output power.)

(3)

Use this

third method when installing a more powerful alternator

and more accessories.

This method will also optimize performance with a

stock system, no additional accessories, and an ordinary

63amp model 10SI DELCO alternator.

It has advantages with the battery up front, and

it’s a “must do” when relocating the battery to the

rear.

Even

with a simple, “stock” system and no added

accessories, this system provides remarkable improvement

to performance. And

if future work might include fans or other accessories, a

more powerful alternator, or battery relocation; then an

excellent system will already be in place.

The system is simple, and the shop work is easy

when working with parts from the M.A.D. catalog.

(See a diagram of the “NEW SYSTEM” below.)

Install

and relocate a new power distribution buss-bar.

(M.A.D.’s Part #CN-1 is shown in the “NEW

SYSTEM” diagram.) The

firewall area is a practical location for the new

buss-bar, as it is approximately a central location in the

electrical system. A

new heavy gauge wire will be routed from the alternator

directly to the new firewall mounted buss-bar.

Remote voltage sensing can be wired from the

terminal block to the voltage regulator within the

alternator. The

new terminal block on the firewall will be maintained at

about 14volts.

When

installing many electrical accessories and a high-powered

alternator, this new layout is often the best plan. When

connection of power for many accessories is needed, the

new terminal block on the firewall will be more convenient

than the original system as the Horn Relay was far

forward. It’s

also the best plan when relocating the battery to the

rear, because the new power distribution will be located

between the alternator and battery, rather than forward

and off to the side at the original Horn Relay location.

This

method places “main power distribution” from the

alternator close to the original dash “main power-up

wire,” which comes to the engine bay from the firewall

bulkhead connector (at the brake master cylinder area).

The original wiring system only has a 12 gauge

“main power-up wire” to the dash area.

And we will see much less voltage drop in this wire

if it is shortened to about 18 inches in length, rather

than routed a few feet forward to the Horn Relay.

The dash area “main power-up wire” shown in the

NEW SYSTEM diagram is simply the original 12gauge wire,

which has been shortened and rerouted to the new terminal

block on the firewall.

In

the NEW SYSTEM, we have installed relays for the

headlights, which removes headlight current load from the

existing dash wiring.

The shorter dash “main power-up wire” and less

current flow through the dash with headlight relays will

certainly improve performance.

Also

notice in the “NEW SYSTEM” diagram, that we have

routed an 8gauge wire from the new terminal block on the

firewall forward to the Horn Relay.

This option is most useful with electric radiator

fans and headlight relays.

Then the main load input of power to the relays can

come from the Horn Relay buss-bar, rather than route

individual wires forward from the terminal block on the

firewall.

When

the battery is relocated to the trunk, we move the M.A.D.

Part # ST-1 solenoid to the trunk, increase the “battery

charging wire” to 8gauge, and re-route the battery

charging wire to the solenoid in the trunk.

(Please see more about trunk mounted battery

systems in our CATALOG page on “Trunk Mount Battery

Helper Kit, Part #TM-1 and #TM-2.”)

For less cost than a tank of 92 octane, our part

#ALT-1 alternator wiring kit will make it simple to wire a

model 10SI or 12SI alternator into the original wiring

system.

This kit can be used with “off-the-shelf,”

factory replacement alternators, such as the 94amp model

12SI DELCO.

And the kit can also be used with more powerful

custom alternators.

It’s

a handy package for alternator up-grades with all three

methods of power distribution discussed above.

The 8gauge Tuff-Wire in the package will deliver

alternator power to the main power distribution buss-bar,

either at the Horn Relay or a new terminal block on the

firewall.

And when used with a factory style three-wire

alternator with built-in voltage regulator, the wiring in

the kit will also support a factory warning light at the

dash.

See Part # ALT-1, Alternator Wiring Kit, in the

M.A.D. CATALOG section.

If the model CS-130 alternator will be added, then

our kit for the DELCO CS series of alternators will do a

good job of wiring for best performance.

The kit can be used with “off-the-shelf,”

factory replacement alternators, or custom versions of the

CS series of alternators too.

The

kit will wire the alternator to support the original

warning light at the dash. The original warning light will work when converting from

externally regulated alternators, and even an original GEN

light on a ’55 Chevy will be operated when wiring with

this kit. 8gauge

Tuff-Wire is included with the kit, and this heavy-duty

wire will deliver alternator output to the power

distribution “buss-bar” (either the Horn Relay, or the

new terminal block on the firewall). See Part # CS-130, Alternator Wiring Kit in the M.A.D.

CATALOG.

NEWER THAN ’71 CHEVY

In

most 1972 models, Chevy introduced a major change in the

main power system. The Horn Relay was moved to the firewall, and the battery

charging wire was routed to the starter, rather than the

battery. Beginning

with 1973, the Horn Relay was moved under the dash, and

then the Horn Relay no longer served as a “buss-bar”

for main power distribution.

With 1973 and newer, a SPLICE in the wire harness

near the back of the engine served to distribute power

output from the alternator.

(Fusible Link wires were at the starter POSITIVE

cable stud, and service was awkward at this location!)

In

these years after 1971, the “main power-up” wires to

the dash area are shorter in length than with the early

Chevy equipped with an alternator.

But with factory splices in the wire harness, and

only 10gauge wire, the addition of a more powerful

alternator and electrical accessories will require a

wiring up-grade.

The

best up-grade method for improving these cars is to

install the “NEW SYSTEM” which is shown in a previous

diagram.

In

the last part of this discussion, we will analyze

performance (voltage drop) and wire over heating.

Also we will

provide recommendations for lengths and gauge sizes of the

“battery charging wire” for custom systems.

Click

here for the last part of this tech feature

|