|

Part 2

BRIGHTER HEADLIGHTS

And

now, a test of performance

after

adding RELAYS for the Head Lights

Relays

can be used as "remote control switches."

It takes only a tiny amount of current to turn the

relay ON. But

when switched ON, the relay delivers power directly to the

accessory. ("high

gain" operation)

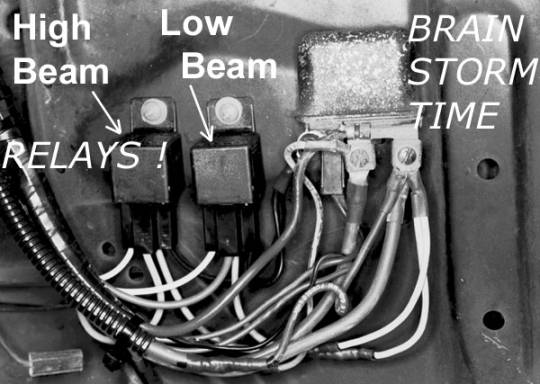

We

can install headlight relays next to the main power

distribution buss-bar at the horn relay (where the old

voltage regulator was).

The

factory "front lighting system" wire harness is

routed just above that area, in route to the headlights.

We can cut and detour the factory High Beam wire

and Low Beam wire to the relays, and now the factory

system will only have to switch the relays ON, instead of

directly powering-up those big headlights.

The

headlights are up front, and the alternator is the source

of electrical power; and the alternator is mounted at the

front of the engine.

It’s logical and sensible to mount RELAYS up

front. Use

existing wiring to switch the RELAYS ON, and then the

relays will send full power to the lights.

(And use of the relays takes headlight current load

away from the dash wire harness, and so the ignition and

entire electrical system will benefit too.)

This

test was done after the relay up-grade,

with High Beams ON, engine at idle RPM.

14.0 volts measured at the horn relay buss-bar.

13.96 volts measured at the back of the headlight.

(Before the relays, we had only 11.5 volts at the

headlight, with 14.1 at the Horn Relay, at highway cruise

RPM.)

This

test was done after the relay up-grade, with

High Beams ON, engine at highway cruise RPM.

(And it's a good thing our testing is finished,

because the engine is warming up with so much

"running in place.")

With

the current load to support the headlights removed from

the dash wiring and switches, we took away the voltage

drop in the wiring to the dash area.

Now

the dash mounted voltmeter will no longer "lie"

to us when we switch the headlights ON.

The ignition will not become weak.

The dash lights will be brighter.

And other accessories will be more powerful too.

The

first time the car was driven at night, the improvement in

the headlights was remarkable!

Now the lights are very bright.

Everyone

who has used our relay kits for the headlight system

agrees that this is absolutely the best-for-the-money

electrical up-grade.

It adds reliability too, by removing current load

from weak factory connections and switches.

Considering the years of hassle free service,

enjoyment, and safety, this is without a doubt the most

sensible up-grade possible.

It beats out expensive and often over-promoted

luxuries like big sound systems, racing ignition systems,

"high-end batteries," chrome alternators, and

gadgets.

Overall,

the headlight relay up-grade makes these old cars and

trucks more useful and enjoyable to drive.

Two

of our part # RLY-1 Relay Kits are required for the

headlight system up-grade–ONE for LOW BEAMS, and ONE for

HIGH BEAMS. (Even

with "two headlight system" cars.)

And

for people who would like to learn more about electricity,

voltage drop, assembly craftsmanship, Fusible Link wires,

and more, we offer the "tech

is made simple"

book. The

book is easy reading, and it's filled with great photos of

craftsmanship and wiring techniques.

Fundamentals of electricity are explained through

cartoon-like illustrations.

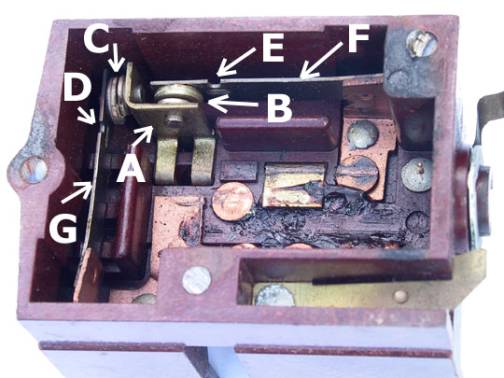

INSIDE OF THE HEADLIGHT SWITCH

(The

switch shown in the photo was removed from a FORD car.

We ground off the rivet heads, punched out the

rivets, and pried the cover from the switch, for a look

inside.)

Call-out

labels with arrows point to various parts of the two

circuit breakers in a typical headlight switch, shown in

the photo above.

A

= Battery

live "buss-bar," which also serves as mounting

for the stationary contact points of the circuit breaker.

B

& C = Circuit

breaker contact points.

D

& E = Resistance

calibration notches in the movable arm part of the circuit

breaker.

F

& G = Movable

arm, metal strip, part of the circuit breaker.

|