Part

Two – AMP

gauge WIRING FIXES

(Dodge was used for

this work shop model)

By

Mark Hamilton

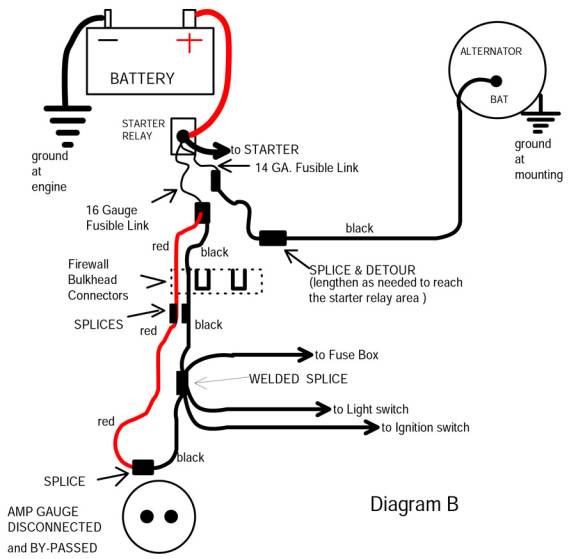

We have seen

the weak areas, now we will make improvements.

The male/female flat blade terminals for the AMP

gauge wires at the firewall connector will be

eliminated–because they are the weakest link in the

system. The

AMP gauge will be disconnected and by-passed–because the

gauge often fails and sometimes it burns dashes.

Alternator output will be routed directly to the

BAT. POS. stud at the starter relay–because it’s the

most direct routing of power.

And, we will make use of both legs of the old AMP

gauge circuit–because it doubles the strength of the

main power-up circuit to the “welded splice,” which

serves as power distribution.

When everything

is working properly, the alternator is the source of power

to the entire electrical system. With this new system, we have alternator output delivered to

the BATTERY POSITIVE stud at the starter relay.

The stud at the starter relay now becomes the

“main buss” for power distribution.

Battery charging current will flow directly to the

battery, via the positive battery cable.

The “welded splice” in the dash wire harness

still serves as a junction for power distribution–but

now we are sending power to the “welded splice”

through both of the existing wires that were part of the

old AMP gauge system.

And the AMP gauge is by-passed.

The system mostly uses existing wires that were already in the wire

harness. But

since we are disconnecting, bypassing, and ignoring the

AMP gauge, we can rearrange the wires to form a much

stronger system. The

male/female terminals at the firewall connector are also

by-passed, the wires now pass directly through connector

body connection.

We

have also used the proper Fusible Link wires for short

circuit protection. A

14 gauge Fusible link is protecting the 10 black wire

circuit to the alternator.

And a 16 gauge Fusible link protects the power-up

wires to the “welded splice,” which serves as main

power distribution to the dash area.

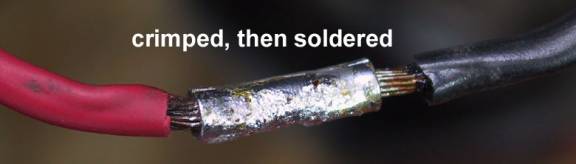

Craftsmanship

and wire splicing methods will be critically important to

reliability with the new system.

We are working on wiring that must handle large

amounts of electrical power every time the truck is

driven. Our

work has to be good or the outcome will be no better than

the weak factory system.

We have to use a few splices to complete the

up-grade, and splicing is a job that not everyone does

well. Resistance

at all spices and connections must be minimized.

Crimp-on butt connectors with yellow plastic

insulation, wire nuts, or twisting and tapping wire

together will not be reliable splicing methods. The old method of crimp first, then solder, then insulate is

still the most reliable.

The

best parts for the job are non-insulated butt connectors,

which are made of copper and are tinned with solder.

Good quality shrinkable tubing will insulate the

splice, and a length of it must be slipped down the wire

before installing the butt connector.

We will also need a soldering gun or soldering

iron, and a lead/tin rosin core solder.

After

stripping the ends of the wires, we slipped shrinkable

tubing down the wire.

Then we crimped the non-insulated

butt connector onto the wires.

And then soldered the connection.

Electrical

tape may be used for the first layer of insulation, before

slipping the shrinkable tubing into place.

(We are using this option because it provides a

little extra padding and insulation over the splice.)

Then slide the shrinkable tubing into place, and

apply heat to shrink the tubing tightly for a good seal.

A disposable lighter works well when there is no

breeze.

A heat gun works very well and is safer too, as it

is flameless.

Hair driers do not produce enough heat to activate

the better shrinkable tubing. (The splice shown in the

photos above is where we have disconnected and by-passed

the AMP gauge at the dash.)

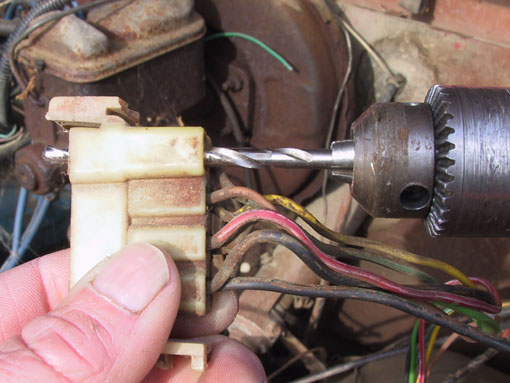

Using a drill slightly larger than the O.D. of a 10

gauge wire, we are drilling out one of the slots in the

engine side of the firewall connector body.

A new wire will pass directly through the connector

body without the weak male/female terminal arrangement.

Both sides of the bulkhead connector must be

drilled–the engine side and the dash wire harness side.

In

the photo above, we are drilling out the dash harness side

of the bulkhead connector.

Before drilling this side, check from under the

dash to be sure that wires are clear at the backside.

And drill just deep enough to go through the

connector–there are many wires at the other side, which

could be damaged by the drill.

This connector body is easily dismounted from the

firewall by releasing the latches.

Removing the connector body and then dragging it

under the dash will allow drilling it from the other side.

With either method, be sure to get the correct slot

so that the holes in both of the connector bodies will be

aligned after assembly.

Often the old terminal is melted into the plastic

connector body and tightly embedded.

If the terminal cannot be removed without breaking

the connector body, then we can use available unused slots

for the new direct pass-through.

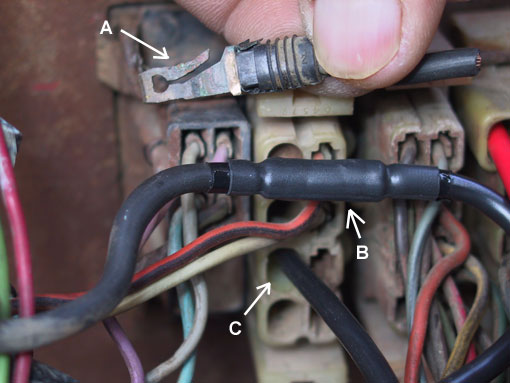

We have cut the original 10 gauge black wire from

the alternator to the connector, and then removed the

terminal with wire remnant from the connector body.

(see arrow A)

Splicing

on a new length of wire has lengthened the original

alternator output wire.

Now it is routed to the starter relay, where a

fusible link will be installed.

(Arrow B points to the splice.)

At the dash side of the firewall connector, we also

cut the wire and removed the terminal from the connector

body. And we

lengthened the wire at the dash side–it now passes

directly through the drilled out connector bodies.

(see arrow C)

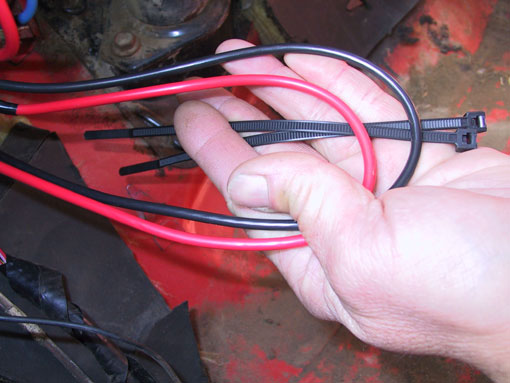

At

the dash side of the firewall connector, we have cut and

lengthened the red and black 10 gauge wires.

Both have been left long enough to pass through the

holes drilled in the connector body and reach out to the

starter relay area.

Plus we added an extra 12 to 15 inches in length,

which will be bundled to the dash harness.

The extra length bundled at the dash side of the

wires will provide opportunity for service work.

Should we ever need to inspect, test, or clean

other terminals at the connectors, we can always remove

the nylon ties and drag the extra length of wire through

the connector bodies.

Then the engine side connector body may be

unlatched and slipped over the 10 gauge wire for access to

terminals in the connector.

The photo at left shows the fusible Link

installations, where the new wires will connect to the

battery positive stud at the starter relay.

The red and

black 10 gauge wires connect to a 16 gauge fusible link

wire, which is actually identified as a metric size on

this particular fusible link.

(1.0 sq mm is the metric equivalent of 16 American

Wire Gauge size.)

This circuit powers up the welded splice in the

dash harness, which powers up all switches, fuses, and

circuits at the entire dash area.

Short-circuit

protection for the black 10 gauge wire to the alternator

is provided by a 14 gauge fusible link (the light colored

of the two, which is actually a 2.0 sq mm metric

equivalent.)

The up-grade really is quite simple, and it does

provide remarkable improvements to reliability and

electrical system performance.

The Dodge alternator/voltage regulator system will

perform well with the up-grade.

Expect more consistent voltage throughout the

system as resistance is significantly reduced at the main

power wiring.

Craftsmanship will have to be good, for the new

system to be reliable.

We are working with the main power delivery to the

entire electrical system.

Current to operate the entire system will flow from

the alternator, through this circuit, every time the

vehicle is driven.

Crimp-on

connectors will not be good enough!

They are prone to “Thermal Run-away” problems,

which is exactly what happened to the crimped on butt

connector shown in the above photo.

M.A.D. offers

very quality non-insulated terminals made of “tinned”

(solder coated) copper, which are perfect for the crimp

first, then solder, then insulate with shrinkable tubing

connections. (As

with the splice that shown in this feature.)

The “tech

is made simple” book, also available in through the

M.A.D. catalog, teaches splicing and soldering techniques,

all about the “Thermal Runaway” problem, and all about

Fusible Link wires.

And the M.A.D.

catalog offers excellent wire strippers and terminal

crimping tool, ideally suited for this kind of work.

|