RELAY

KIT ORDERING & Tech Tips

We use the same Relay kit for

many systems, rather than sell different versions of the kit for

all the many important uses.

We have included more than enough parts, diagrams, and

information in this kit to make it complete for most

installations.

Many people have originally

ordered one or two kits; and then after learning more from the

book and seeing all the parts in the kit they order more relay

kits. The modern,

well-equipped Hot Rod will require at least a few relays for the

best electrical system performance and reliability.

Most people who get these kits comment that they have

enjoyed learning about using relays and notice the remarkable

improvements with electrical system performance.

for HEADLIGHT SYSTEMS

TWO

relay kits are needed; one will serve the Low Beams and

the other will serve the High Beams.

It’s the same with “two-headlight systems” and also

with “four-headlight systems.”

(In Example: A

’55 Chevy or a ’71 Chevelle has the “two-headlight

system.” The

’66 Chevelle and also the ’70 Chevelle are examples of cars

with the “four-headlight system.”

Although the front of the cars look quite different, all

of these cars will need two Relay kits for the Headlight system

up-grade.)

HEADLIGHT SYSTEM DESCRIPTION

In

American-built cars and trucks from the Muscle Car period (and

before), the High & Low beams have separate wires routed

from the beam select switch forward to the front of the car.

We typically do the wiring work for the relay

installation under the hood.

The original wire harness can be opened at the area

approximately between the front wheel and the radiator core

support. At this

part of the car’s wiring there will be only one wire for the

Low Beams and another wire for the High Beams.

These two headlight wires will be interrupted and

detoured through the relays.

Lamps

for the “two-headlight system” are constructed as a

two-lamps-in-one system, which is why these lamps have three

terminals. With

these three-terminal-lamps; one terminal serves as the ground

for both High & Low beam filaments, a second terminal is

POSITIVE power input for the low beam filament, and the third

terminal is POSITIVE power input for the high beam filament.

The “outside” lamps in the “four-headlight

system” also have these same three terminals—and then the

“High Beam only” lamps at the inside will be

“jumper-wired” to the High Beam wires at the outer lamps.

Also…

With most American built cars and trucks from the Muscle

Car period (and before), the “front lighting system wire

harness” begins at the firewall bulkhead connector, and routes

forward along the driver’s side fender, in the engine bay.

The wires first route to the driver’s side lamps, and

then “jumper wires” extend over to the passenger side lamps.

In a few models of cars and trucks, there will be a

splice where the High Beam wire and also the Low Beam wire will

fork-off to the right and left side lamps. The splice is typically near the radiator core support area,

where these circuits fork-off to left side and right side.

Therefore

we recommend detouring the wires at the area between the front

wheel and the radiator core support, which will put us ahead of

the splice. The

High Beam and the Low Beam circuits will each have only one wire

at this area. Details

of the relay installation is diagramed and discussed in the

Relay kit manual.

(And

we hope that the above explanation of factory-wired headlight

systems will clear up the many misunderstandings about the

headlight system, and also the need for two Relay kits for the

up-grade.

Also

please see our Electrical Tech section feature story on Brighter

Headlights.)

for ELECTRIC RADIATOR FAN

SYSTEMS

TWO

relay kits should be used with most electric radiator

fan systems. With two small diameter fans, we prefer one relay kit per

fan. And with one

large radiator fan (16” diameter or larger), we prefer two

relays wired in parallel. (And

instructions with diagrams for these installations are included

in the relay kit manual.)

The

reason for our recommendation is to prevent slow-meltdown of the

wire harness connector at the base of the relay.

Electric motors are prone to overheating connections and

switches in power delivery circuits.

Two Relays can handle most fan systems.

However, with only one relay pulling the entire load for

powerful radiator fans, then the terminals will often overheat

if the fan system is used for long periods of operation.

Meltdowns

often occur with the “Male/Female-Flat Blade” terminals in

continuous duty/high current demand automotive

systems—especially with power loads to electric motors.

The current load limitation that these relays can handle

is with the wire connection design that will join the wires to

the Relay. (Rather

than the contacts inside of the relay being the “weakest

part.”) It’s

why it will do no good to compare the current rating published

on the Relay to the “RMS” current draw rating of a radiator

fan motor.

We

are using the best possible terminals with these relay

connectors, but it’s still best to use a pair of relays for

most electric radiator fan systems.

Two relays sharing the load will create a strong power

delivery system; but one Relay for a radiator fan system will

likely have problems.

The

same type of “Thermal Runaway” problem is also likely to

cause failure of the ordinary “cartridge type” in-line fuse

holders—It’s why we have supplied the 18gauge Fusible Link

in our Relay kit. (Learn

more about “thermal-runaway” problems in our tech book,

part#TB-1, ELECTRICAL WIRING “tech is made simple.”

And

what about using just one, larger, 70 amp “rated” relay,

which could have screws & ring terminals for the fan relay

“load circuit?”

Yes, it could be done; and yes we could sell those too,

but we don’t. It

only makes good sense to keep all of the relays on a car the

same, when a few relays will be installed.

Presently,

the “standard format” relays in our kit are the genuine

Bosch item, and replacements (Bosch or others) will be found at

many stores where auto parts are sold.

The larger, and other types of less-popular relays will

not likely be found at most neighborhood Auto Parts stores.

The difference could be compared with attempt to find a

body-trim part for a ’70 Chevelle Super Sport / or a four-door

’63 Fairlane. (Ha!

And good luck with searching for the Fairlane parts.)

Also

we should consider that greater reliability may be added with

the “redundant parts/built-in backup” installation method at

important systems. It’s

exactly the reason that for many years most small airplanes used

TWO MAGNETOS for the ignition system.

In fact part of the pre-flight test included a

verification procedure to check that each of the two magnetos

were functioning well—And that either magneto could keep the

plane airborne. With

our own cars at M.A.D., we always use more than one of the relay

kits for the radiator fan system.

Typical

air conditioning systems, electric fuel pumps, and many other

systems should use only one relay. The current

demand with these applications is not so large an amount as to

require two relays. Reliability

has been very good with one relay used.

(With the thousands of relays in the years that we have

sold this Relay kit, we have not yet heard of a single failure

in these applications with only one relay used to handle the

power-delivery load.)

The Relay kit

manual contains diagrams for all of the systems discussed above,

and many more too.

Mostly, we use relays as heavy duty, remote control switches.

A main power wire delivers full power into the relay. The relay is switched "ON" with only a very small amount power, then it

®"relays"® (sends onward) a big "load" of full power directly to the accessory. Headlights, electric radiator fans, fuel pumps, air conditioning, and driving lights are all examples of power hungry systems, which are at their best when powered-up by relays. Using a relay can short-cut power delivery, which prevents the voltage drop associated with lengthy wiring circuits. (Without relays, power will be routed from under the hood, to the dash area, through dash wiring and switches, and back under the hood to the part–A lengthy circuit indeed!) The alternator is the source of

power, and it is mounted on the front of the engine. It's sensible to mount relays up front and let them send full power to lights, radiator fans, and other accessories. The relay also provides circuit isolation, and prevents overloading existing wiring and switches.

| Lights are brighter, fans are more powerful, and in general everything works better with RELAYS. Electrical parts are designed for best performance at 14 volts. RELAYS deliver full 14 volts | | If you haven’t been using Relays, you have been missing out ! | The modern, up-graded HotRod will often use several relays, each doing different jobs. (for headlights, fans, fuel pumps, and other accessories) Relays isolate systems and deliver full power for the best performance. Best Buy The best buy in electrical system technical information is purchase of at least one of our Relay kits and our “tech is made simple book.” The relay kit comes with a great manual, and the best of parts for real-world, hands-on experience with an easy to do workshop project. “tech is made simple” covers a lot of useful information that our industry has been ignoring. And “tech is made simple” has many close-up photos of workshop procedures.

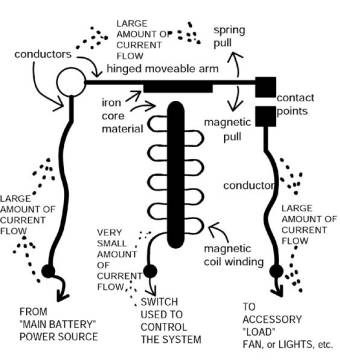

How

Relays Work

The switch used to control the system (fans or other accessory) only handles a very small amount of current flow, which will power the “magnetic coil winding” in the relay. The magnet resulting from current flow through the coil winding will pull the movable arm, which closes the contact points. The contact points serve as the “make or break” switch between the main power source and the accessory (fan, etc.). It’s the relay that handles the heavy current flow to the accessory–not the switch used to control the circuit. Placement of the relay somewhere between the power source and the accessory will provide the most direct route of power delivery. And a long wire of small gauge size with a small delicate control switch works fine, because the coil winding in these relays will only draw 0.08 amps! |